It could help cut carbon emissions by reducing the need to use air conditioning.

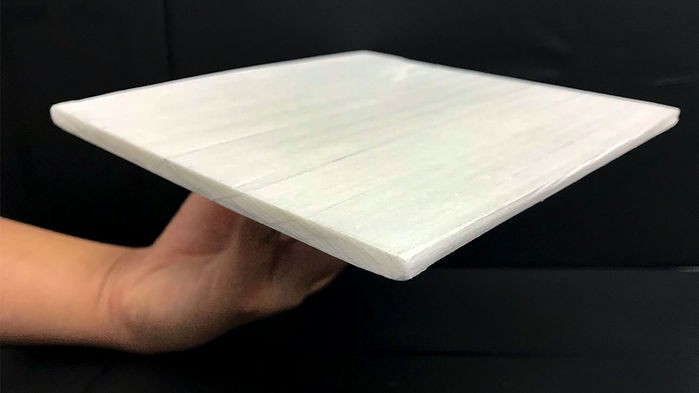

How it was created: A team from the University of Maryland stripped out lignin from wood. Lignin acts like a sort of glue holding molecules of wood’s other main component, cellulose, together. But it also absorbs infrared light, which means the wood warms up in the sun.

The researchers heated and compressed the remaining cellulose, creating an engineered wood that’s eight times stronger than the natural variety.

Its properties: The engineered wood is not just strong. The pale-colored cellulose reflects almost all incoming visible light and absorbs very little infrared light, reflecting it away. It is also able to absorb heat from its surroundings, and radiate it back out. It can cool down surfaces it’s attached to by up to 10 °C and could reduce energy costs by 20% to 60%, according to a paper in Science.

The potential impact: Air conditioning is a significant, and rapidly growing, contributor to global warming. It creates a vicious circle, pumping out heat from buildings, which then increases the need to use AC. Buildings made from this engineered wood should let us rely on it a little bit less.

Some caveats: It’s a useful contribution to the field of heat-reducing materials, but it would be much more expensive than standard wood, which is rarely used for roofing. Much of the growth in dwellings around the world is in the form of urban apartment blocks, which are often made of cheap concrete. This sort of wood could potentially be used as external cladding, but it’s flammable and less durable than other materials.