Business Impact

Audi Drives Innovation on the Shop Floor

A carmaker’s automated body shop illustrates how German manufacturing is moving forward.

At first, I’m apprehensive about entering the laser chamber. Its 13-kilowatt diodes fire blasts of energy powerful enough to melt metal. At the moment, they are ready to join the roof and wall frame of an Audi A3 sedan. But the engineer at Audi’s plant in Ingolstadt, Germany, insists that I see up close the “invisible” laser-brazed seam about to be made, including a minuscule bend, just five millimeters around, that prevents the car’s body from corroding when exposed to the elements.

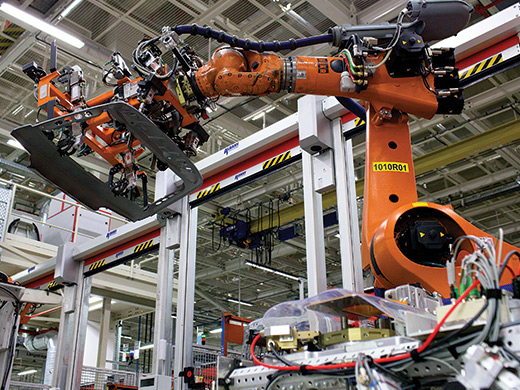

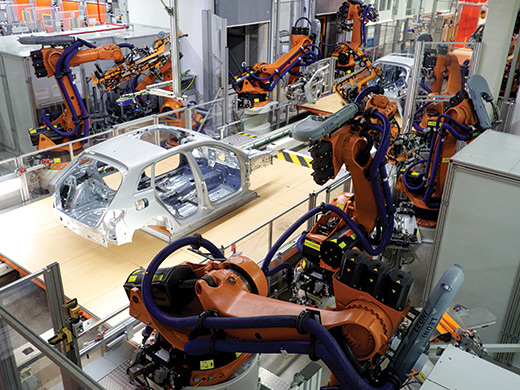

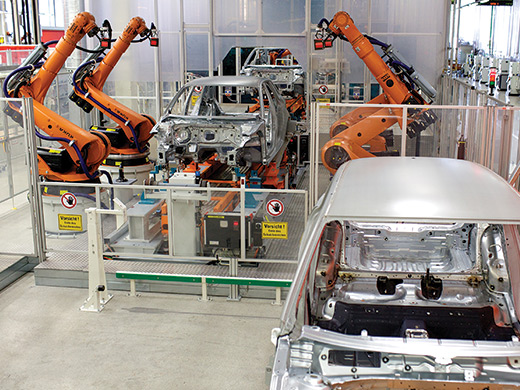

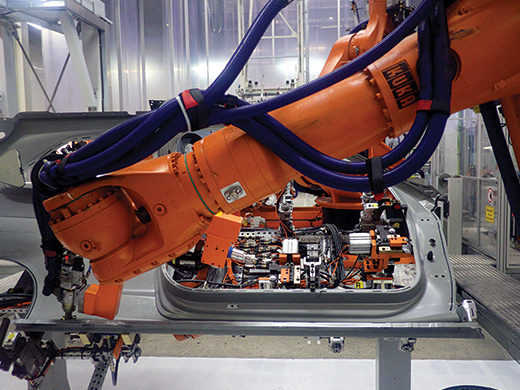

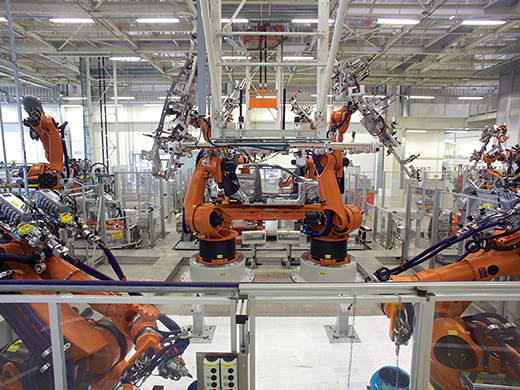

The shell of the car sits in the center of the chamber and is surrounded by robotic arms, one of which aims what looks like a soldering iron. The laser brazing process, like much else on the 540,000-square-foot factory floor, is automated and secured behind barriers or within a closed chamber. Later, when I do see people inside the factory, they tend to be pedaling down the long, spotless corridors on red bicycles.

Hubert Hartmann, head of the A3 body shop at Ingolstadt, calls it the most modern factory floor of its kind. “It is like a Swiss watch, with the same level of precision,” he says as machinery whirs nearby with preprogrammed exactness. While most auto plants use robots for welding and other dangerous tasks, Audi marries a high level of automation with a multitude of other advanced manufacturing technologies, including low-power lasers driven by optical sensors; innovative combined bonding and welding, which saves both production time and car weight; and regenerative braking in lift and conveyor systems to reduce energy costs.

Despite relatively high wages, long vacations, and strong labor laws and regulations, Germany remains a global leader in many manufacturing sectors. Last year, automotive and industrial exports helped the country post a record trade surplus of 198.9 billion euros ($269 billion). One reason: automation. Contemporary German auto manufacturing exploits advanced manufacturing technologies to increase productivity and profits. As a result, manufacturing employment has dropped. Between 1970 and 2012, the proportion of German employment in manufacturing fell by half, to around 20 percent (nearly double the U.S. share).

At Audi’s A3 body shop in Ingolstadt, the robots are roughly equal in number to the 800 employees. They do most of the heavy lifting, as well as potentially dangerous spot welding and bonding, and tediously repetitive testing. To Bernd Mlekusch, head of technology development production at Audi, the benefits of automation include much higher productivity and reduced demand for untrained workers. At the same time, workers with more training and greater specialization are increasingly needed, he says. German automotive workers, and German manufacturing workers in general, are already paid significantly more than their American counterparts.

The INTA and group framer machines at Audi exemplify the shift toward automation. INTA, or Ingolstadt automatisierter Anbau, is a fully automated door-assembly process that uses an array of sensors, robotic arms, and lifts. As an A3 body is lowered into place, a sensor determines which version of the car—two- or four-door—is coming down the line. A set of robotic arms then fits hinges to the body while another set picks out the correct doors and prepares to mount those to the hinges. Until 2012, this was done manually, says Carsten Fischer, who is responsible for add-on parts, such as doors, at the plant.

The group framer, which does its work in the middle of the body-assembly process, is less ballet and more brawn. It attaches the large structures, like the sidewall frames, to build what we’d all recognize as the body of a car. In a few seconds, roughly 80 spot welds are made by nine robotic arms moving in and around an 18-ton metal contraption that holds the various parts together. The group framer does this without any human intervention and, because of the use of sensors and components that adjust automatically, can switch between as many as three different car models on the fly as they come down the line.

Audi works with KUKA, a leading industrial-robot maker based 84 kilometers away in Augsburg, which in turn works with the Fraunhofer Society, a group of over 60 applied research institutes, jointly funded by industry and the government, whose goal is to facilitate the sort of forward-looking research that a small or medium-sized company might not be able to fund on its own. The innovations that come out of Fraunhofer projects filter back through the whole industry, and experts credit this network of small and large companies and public-private research groups with helping German manufacturing thrive in an era of intense global competition.

The relationships spur innovation but, importantly, also help solidify standards necessary for those innovations to be widely adopted, explains Andreas Müller, who manages RFID technology at Bosch, another company involved in automating factories.

One project Bosch is working on is a German government initiative to use sensors and software to create even smarter factories. The idea is to take the automation in individual processes at a place like Audi’s factory and extend it so that every shipping box, component, and manufacturing station will log and share data, Müller says. Today’s highly automated factories share data mainly within a single process or on a single factory floor—say, between a machine that scans a car to determine its body type and a second machine that selects a tool of the right size for that body type. The government initiative aims to go much further.

The vision is that data from every step of production will not simply pass from one shop to another within a business—such as from Audi’s body shop to its paint shop—but will eventually transit between different partnering companies, optimizing the production process without human input by altering speeds, predicting which components are likely to have been damaged during shipping or tooling, changing the order in which items are built, and reordering parts from suppliers.

Audi’s cars are not entirely built by computers and robots, of course. As I pass by an area where people attach mudguards, rear fenders, and a few other parts, one of the engineers chaperoning my visit explains that some stages of physical production are still worker-intensive, whether because of the size or location of the parts involved or the need to perform certain tasks with a precision that robots aren’t currently able to achieve.

So far the robots can’t do these specialized jobs, the engineer explains, but, he adds, “we’re working on it.”