Artificial Intelligence / Robots

These AI Hotshots Plan to Reboot Manufacturing by Jumping Inside Robots

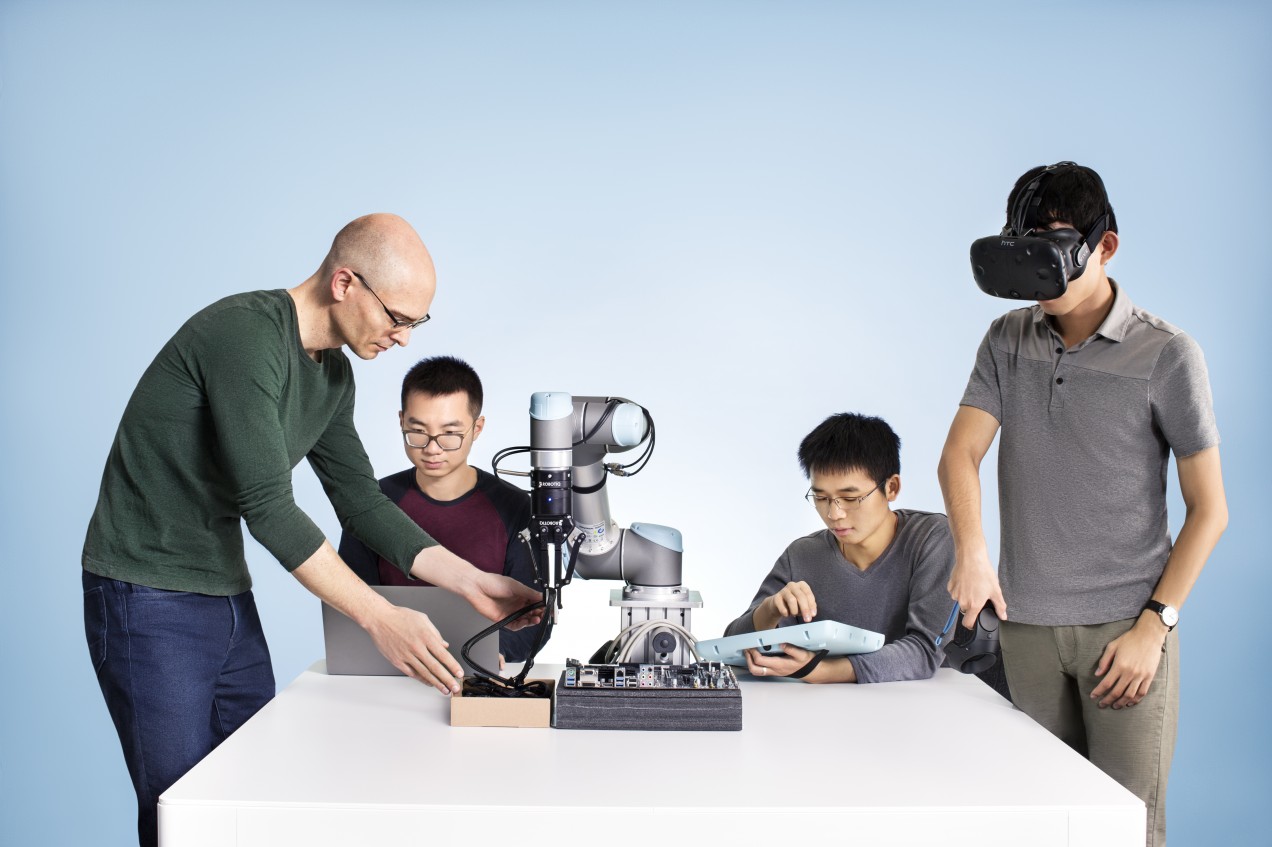

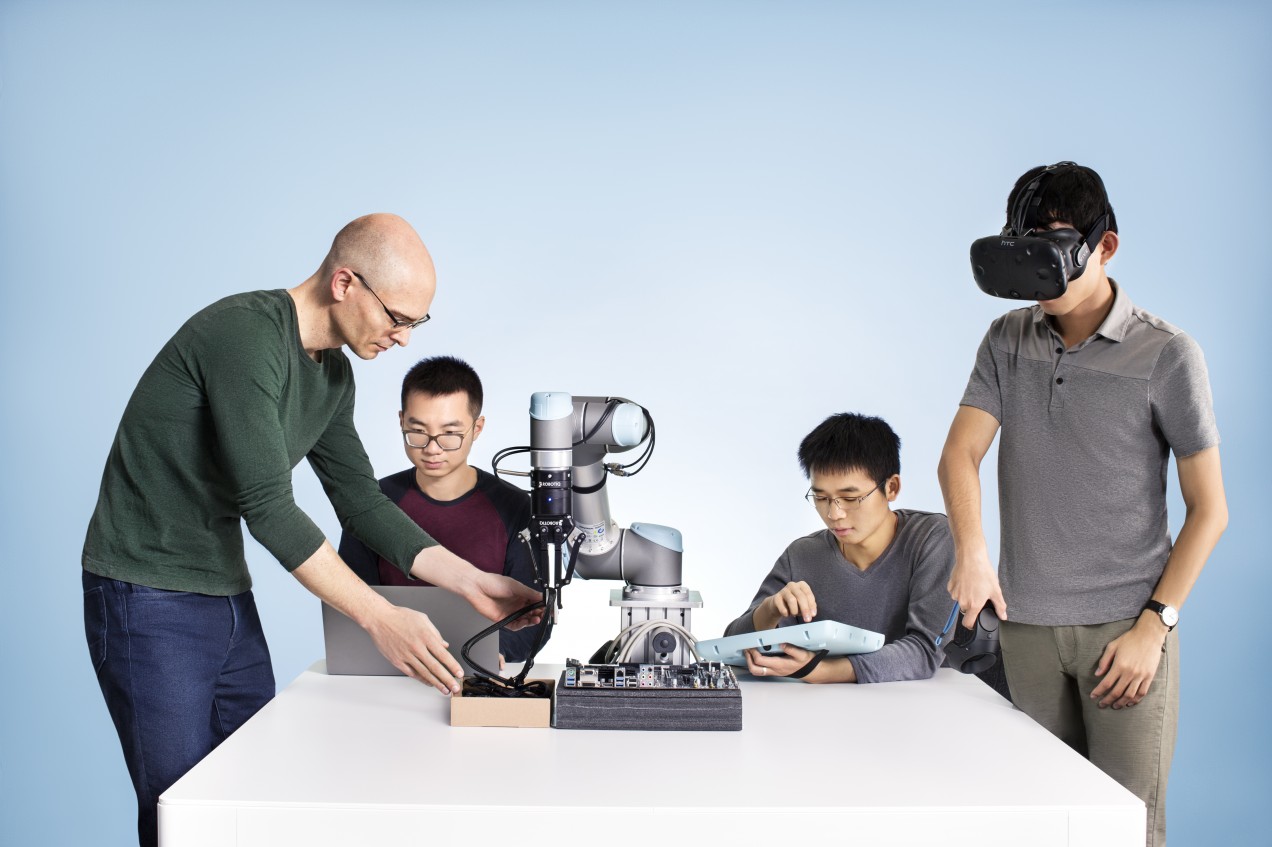

The startup Embodied Intelligence is developing smart manufacturing robots that learn from human workers through virtual reality.

Robots are taking over a growing number of manufacturing chores, but they remain relatively clumsy and slow to program.

A startup called Embodied Intelligence plans to change that with robots that learn through observation, experimentation, and repetition. And they will be trained by human tele-operators wearing virtual-reality goggles.

If the startup can achieve some of what it aims to, it could have a huge impact on manufacturing and perhaps other industries. New approaches that make robots more adroit and quicker to learn would shake up the way work is done.

Embodied Intelligence was founded by Pieter Abbeel, a professor at UC Berkeley, along with several of his star students. Abbeel is an expert in machine learning, and he has done some groundbreaking work training robots to do difficult tasks through practice and experimentation (see “Innovators Under 35: Pieter Abbeel” and “10 Breakthrough Technologies 2017: Reinforcement Learning”)

“The goal is to bring the cutting-edge research to robotics and manufacturing,” Abbeel says. He says the techniques his company is developing will enable robots to do a range of things that are currently too time-consuming to be programmed in.

This will include picking complex shapes out of bins, assembling electronic components, and manipulating deformable objects such as wires, cables, or fabrics—skills that could translate well to advanced manufacturing settings.

The company will use several newer machine-learning methods, including deep reinforcement learning, deep imitation learning, and few-shot learning. Each approach tries to mimic the capabilities that still set humans apart from machines when it comes to learning.

But while Abbeel and his cofounders are doing impressive work on machine-learning algorithms, he says that what will really help teach robots new skills more quickly is the use of tele-operation and virtual reality.

“You can put on a VR headset and immerse yourself inside the robot,” Abbeel says. “The human is doing all the control and thinking, and you get very, very clean data collection. The things we’re interested in cannot be done with existing automation—they are just completely out of scope.”

The technique is catching on elsewhere as well. Researchers at Google DeepMind, for example, have begun exploring how virtual reality can enable robots to learn more efficiently. And a company called Kindred AI, based in Vancouver, Canada, and San Francisco, is already using tele-operated robots and reinforcement learning to do simple picking tasks for companies including the clothing maker Gap (see “How a Human-Machine Mind-Meld Could Make Robots Smarter”).