Humans and Technology

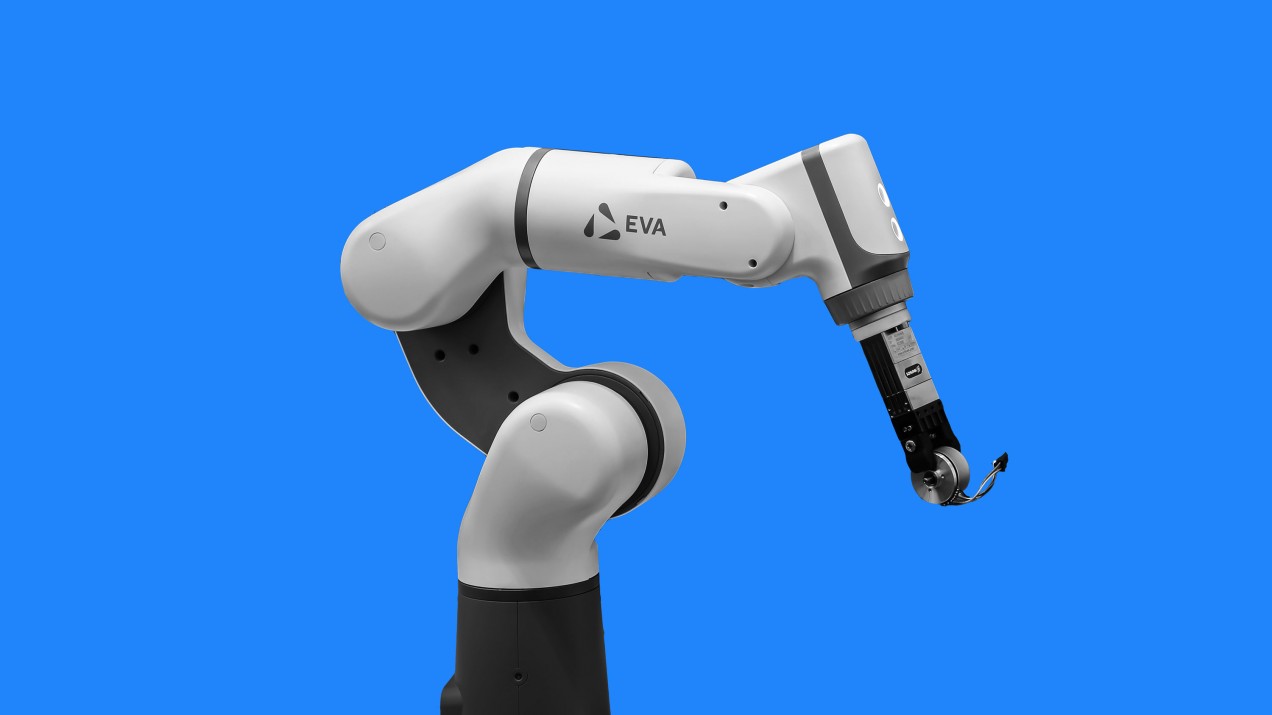

Anyone can program this cheap robot arm in just 15 minutes

Automata hopes its inexpensive devices can bring automation to companies that usually wouldn’t be able to afford high-end robotics.

Industrial robots don’t come cheap—the top-end ones can cost more than $100,000 each. No surprise, then, that relatively few small companies own one, and even large companies haven’t adopted them at the rates you’d expect.

Automata, a robotics firm in London, thinks it can fix this lag in uptake. Its robotic arm costs just $7,500 and is sold under the name Eva (yes, it is named after the robot in WALL-E). The company hopes to widen access to robots by focusing only on the more basic functions that small firms actually need. It is backed by $9.5 million from several investors, including robotics giant ABB.

Eva was designed with small-scale production in mind. It’s light enough to carry in a backpack, and compact enough to sit on a desk. More important, it’s designed to be easy to use. Its software can run on any device and includes drag-and-drop functions. Automata says that anyone can learn to program it in just 15 minutes with minimal or no training.

Automata

That’s important, because the biggest barrier for small and medium-size companies isn’t just the one-time cost of the kit. It’s also the need to hire someone to maintain and program it, says Julie Shah, an associate professor at MIT’s Computer Science and Artificial Intelligence Lab.

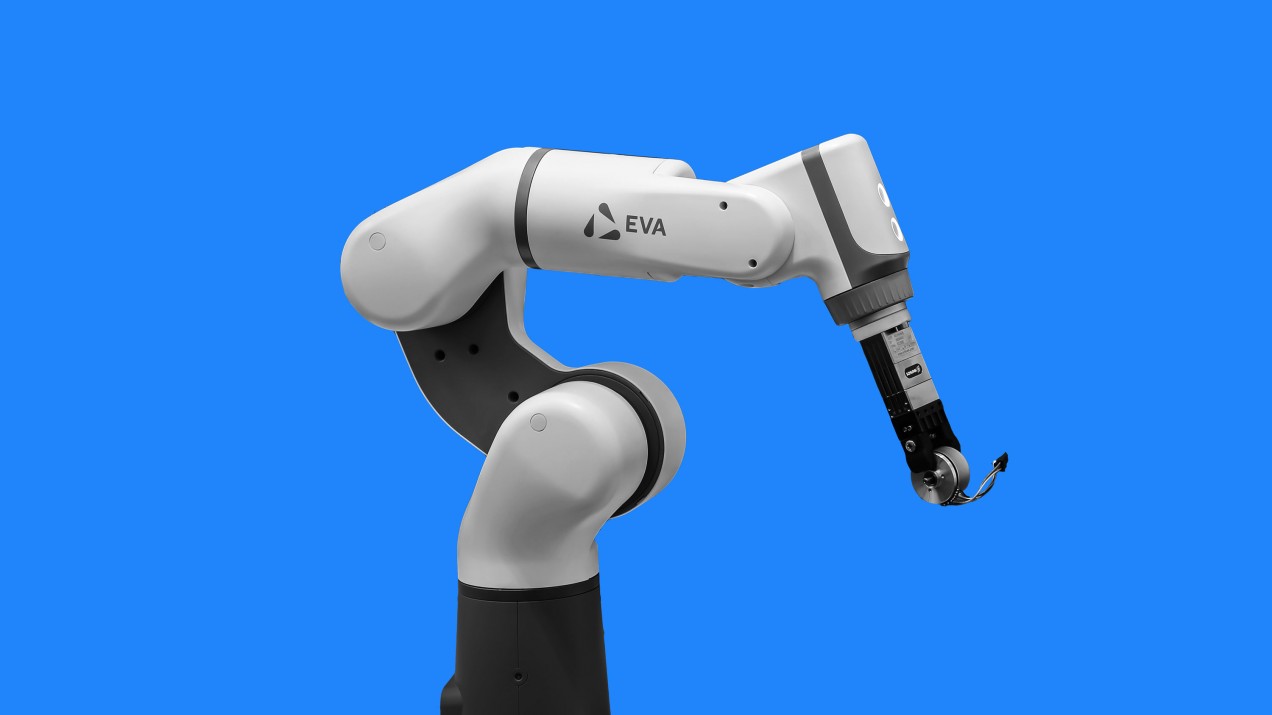

The relatively low initial cost should be attractive for smaller businesses, too, the firm hopes. It managed to get the price down by bypassing traditional production routes, according to founders Mostafa ElSayed and Suryansh Chandra. They have spent the past four years designing, tweaking, and fine-tuning the robot.

Automata

Rather than buying components off the shelf from one of the two potential external suppliers, they designed the robot’s gearbox from scratch, choosing cheaper parts, the pair say. There will be a necessary trade-off between cost and precision, but Automata hopes that its robot will fill a low-cost niche for its customers that hasn’t been filled before.

Most of these customers are small and midsize manufacturers from a range of established industries, including metal fabrication, electronics, pharmaceuticals, and packaging. Eva is replacing simple, repetitive manual tasks such as product testing, placing things on conveyor belts, sorting, dispensing, and inspection, for example. One customer is using Eva to test smartphones.

By stripping out unnecessary functionality, Automata says, it has managed to make a device 80% equal in precision and performance to world-leading robots from big firms such as Kuka or Yasakawa, but at roughly 20% of the cost.

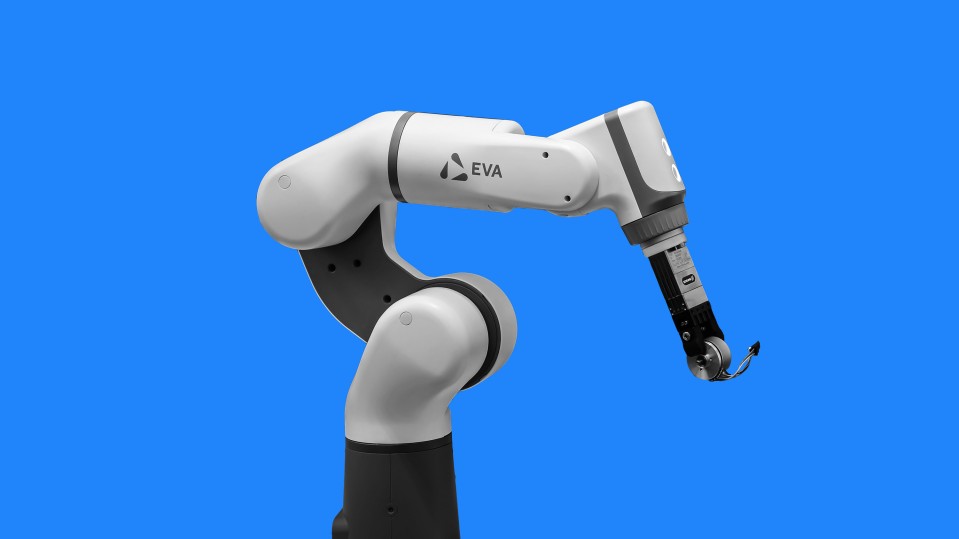

But robotics is a tough field to crack. Boston-based startup Rethink Robotics had to close last October, despite its impressively safe and easy-to-use machines Sawyer and Baxter. It will be hard to survive without access to a significant sales and distribution network, warns Henrik Christensen, director of the Contextual Robotics Institute at UC San Diego. Automata could also be at risk if one of the big tech companies decides to muscle in on the territory.

Still, Automata think its appeal to smaller firms can help it succeed where others have failed.

“Automata could potentially have a big impact pushing automation and robotics through to smaller companies,” Shah says. “It’s very exciting.”

Advertisement