You could say we grew up together, Hubble and I. Most people trace Hubble’s start to a report written in 1946 by Princeton astronomer Lyman Spitzer. I was born in Paterson, New Jersey, on October 3, 1951. As I grew through my childhood and teen years, Hubble languished in a state of arrested development, while the technologies of the new space age matured enough to bring Spitzer’s vision into the realm of the possible. By delightful coincidence, the two of us began the final stretch of our journeys to space at almost the same time, with my astronaut selection and Hubble’s congressional approval both occurring in 1978.

Hubble is an amazing piece of engineering. What makes Hubble radically different from anything built before or since is that it was designed to be maintainable by two people in bulky space suits while orbiting hundreds of miles above the Earth. That’s like working on your car while wearing an inflatable sumo wrestler suit and boxing gloves, with the added twist that your tools float away if you let go of them.

The principles for maintainable design are simple ones that are familiar to anyone who has ever done the least bit of home or car repair: things are easier to repair when the layout of parts is simple and uncluttered, no healthy units need to be disturbed to get at the failed unit, the fasteners and connectors are standardized, and few unique tools are needed. How did a bunch of people who had never been in orbit or worn a space suit figure out what “maintainable” meant in a microgravity environment, and then incorporate all that into the telescope’s design?

Two innovations provide good examples of the inventive and exacting work done during the early stages of Hubble’s design. The difficulty of servicing Hubble put a very high premium on simplifying tool interfaces for efficiency and reducing the overhead associated with getting set up for work.

Designer Henry Ford (no relation to the automotive family) decided to tackle the first of these by limiting the variety of fasteners used on the telescope. He set off in search of the smallest possible bolt that had the necessary high-tensile strength and a reasonable breakaway torque. In plain English, that means a bolt strong enough to withstand what he guessed the forces would be during a shuttle launch (the shuttle was still on the drawing boards, so there was no firm data), but not too hard to loosen with a wrench. Settling on a particular high-strength bolt with a double-height 7/16th-inch hexagonal head, Ford began his quest with the electronics installation team. This team’s job had always been to make sure that no electronics box ever came loose from its mountings; removing bolts in orbit had never occurred to them. After several rounds of argument and analysis, they agreed to use his chosen bolt on all of their units. Next, Ford went to the mechanisms team, responsible for things like the solar array and antenna hinges and latches, and finally the scientific instruments team. When he was done, he had collected the engineering data needed to prove the bolt was suitable for every application and had the commitment to use it from each system’s lead engineer. NASA would later make this the standard bolt on the shuttle and space station for anything that might be repaired in a spacewalk, or EVA [extravehicular activity].

Tom Fisher’s invention took aim at the time involved in worksite preparation. He knew the 38 EVA worksites on the telescope better than anybody else, having made by hand the precise and detailed engineering drawings of each location and the body positions that would allow suited astronauts to reach and operate all the maintenance fittings. Fisher saw the need for a portable EVA work platform, known as a foot restraint, that was more versatile than the simple one NASA envisioned using.

A portable foot restraint is to astronauts what gravity is to earth-bound mechanics: the thing that allows them to anchor their feet so they can exert leverage or apply force to their tools. Try to turn a bolt in the microgravity of space without a foot restraint, and you will find that your free-floating body turns instead. Early foot restraints were basically plates on poles. They were designed to stick straight out from the structure to which they were attached. The foot plate could only tilt in one axis and could not be adjusted while in use. Fisher came up with the idea of adding pedals to the foot plate so astronauts could swivel their bodies with the tap of a boot. We would refine Fisher’s initial concept through a succession of neutral buoyancy tests starting in 1985, eventually producing a highly versatile device that flew on every Hubble mission and is now in use aboard the International Space Station.

For the first two minutes and 15 seconds, the ride was turbulent and loud, like being in a wild combination of earthquake, rock concert, and fighter jet. The vibrations were almost bone-rattling; the thrust pushing upward through my back strong and constant. I felt the thrust tailing off, heard Charlie report that the solid rockets were burning out as expected, and then heard the thump that announced they had been jettisoned. Now the ride seemed quiet, and as smooth as an electric train. When the engines cut off six minutes later, the lightness in my limbs and the checklists floating at the end of their tethers confirmed that I was back in orbit. I felt instantly at home.

We ended our first day in orbit in high spirits. The robotic arm was working well, the telescope showed no sign of damage from the harsh forces of launch, and our space suits checked out perfectly.

Hubble deploy day for us began with an entirely forgettable wake-up tune and the routine start-of-day tasks: dress, grab a bite of breakfast, review the morning message package, update the shuttle’s navigation data, and make sure all of our middeck experiments were running properly. The carefully crafted deployment plan began to fray as soon as Steve started to lift the telescope out of the cargo bay. The game plan for deploying the telescope’s appendages, as the solar arrays and antennas were called, began to unravel next. Almost every step in this plan revealed that the ground control team at the Space Telescope Operations Control Center had not fully appreciated the complexity of Hubble’s systems and was struggling to deal with the pace and stress of real-world spaceflight operations.

Our high hopes for a spectacular first image from Hubble came crashing to Earth a few weeks later, when the world learned that the multibillion-dollar space telescope we had just put into orbit had blurry vision. Charlie and Steve spent many long weeks worrying that they might have caused this by bumping the telescope as they lifted it gingerly out of the shuttle’s cargo bay. They must have been the only two people on Earth who were relieved to learn that Hubble’s 96-inch-diameter primary mirror was the wrong shape. It was too flat at the perimeter by 0.0001 inch, which is about 1/25th the diameter of a human hair or 1/40th the thickness of a typical hardcover book page.

This was unbelievable news, an unthinkable error. A tidal wave of shock and anguish swept over NASA and the Hubble science community. Congress and the media erupted in outrage. The pain was written clearly on the ashen faces of the NASA officials who broke the news to the public.

Launching the first maintenance mission two to three years after deployment had long been the plan, but nobody had ever imagined that the Hubble mission’s life would be hanging in the balance the very first time out.

As is so often the case, the trick to finding a solution was to recast the problem. Did the mirror itself really need to be fixed? Suppose instead that the real challenge was to correct the light that it reflected into the instruments? One happy circumstance—the lone little sliver of good news in an otherwise truly horrible fiasco—suggested that this might be possible. The mirror’s shape was indeed wrong, but it was precisely wrong. This meant the engineers could calculate very precisely the difference between its actual shape and the shape it was meant to be. This information could then be used to calculate the correction that would restore the telescope’s vision, much as an optometrist determines the shape of the prescription lenses needed for a pair of eyeglasses.

By October, the team had the outlines of a recovery plan in hand. One of the four large scientific instruments in Hubble’s aft end would be replaced with an identical box containing the corrective optics—small mirrors in Hubble’s case, rather than lenses. These mirrors would provide properly focused light to the telescope’s guidance sensors and the three remaining instruments. Similar mirrors would be built into the replacement unit for Hubble’s main imaging instrument, the Wide Field/Planetary Camera, which was already under construction.

Four other shuttle crews would visit Hubble over the next 16 years. Every servicing mission improved upon the existing methods and invented new devices to tackle ever more complex repairs, but all relied heavily on the tools and equipment produced by the original team. By the fourth mission, the Hubble repair teams were doing things that we never would have contemplated back in 1990, such as taking the lid off a delicate scientific instrument mounted just a few feet below the primary mirror in order to change individual circuit boards.

Over the course of the five maintenance missions, 16 spacewalkers would spend a total of 165.8 hours—just six minutes shy of seven full days—riding the shuttle’s robotic arm or clambering around the telescope. Thanks to these missions, the telescope today is a far better instrument than the one we first deployed on April 25, 1990. Its reliability, data storage, and data transmission rates all rose as space shuttle crews replaced the original vintage-1970s electronics with state-of-the-art solid-state components.

A threefold increase in sensitivity allows it to see deeper into the universe. Hubble’s cameras are 100 times better today than they were at the outset, and its spectrographs are 10 times better. All these advances allowed Hubble to measure the expansion rate of the universe, known as the Hubble Constant, almost five times more precisely than the preflight design goal, and to become recognized as the most productive observatory ever built.

Essentially all that remains of the Hubble we carried aloft in 1990 are the two mirrors and the metering truss that holds them, the yellow EVA handrails and foot restraint sockets, and the shiny silver outer skin that makes this magnificent flying machine so easy to spot when it passes overhead at twilight. That silver skin sparkles much less than it did on the day I first saw Hubble back in April 1985. Much of the decay is due simply to the harsh environment of space. All satellites “weather” as they are bombarded constantly by micrometeoroids, bits of space debris, intense radiation, and the charged particles in the solar wind. Hubble is alone among satellites in being affected by another weathering force: human contact. As they went about their vital tasks, the spacewalking astronauts who maintained the telescope left their handprints on its outer skin.

These visible handprints are like the tip of an iceberg, dramatic hints of a larger mass that is out of sight. To me they symbolize the countless earthbound hands that designed maintainability into the telescope, built the tools and equipment needed to make in-orbit servicing a reality, trained the flight crews and worked each mission as tirelessly as the astronauts themselves. Each of these unsung people can rightly claim to also have left handprints on Hubble.

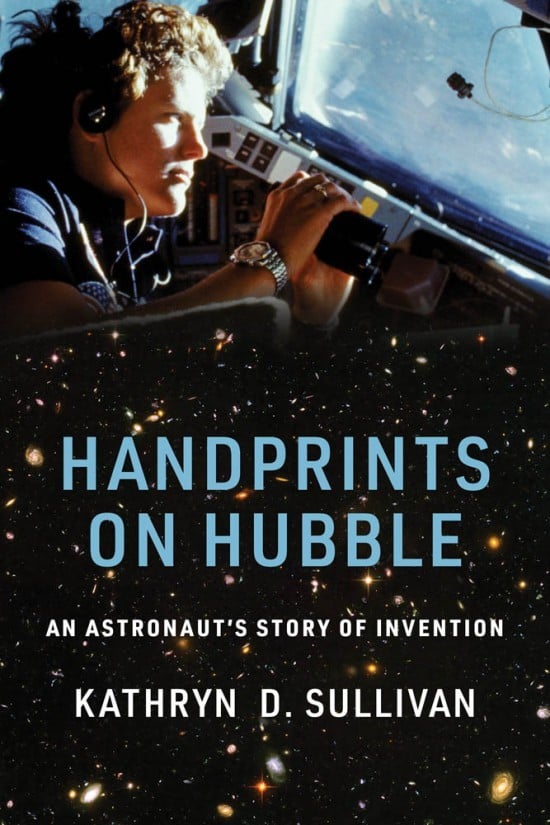

Kathryn D. Sullivan is a NASA astronaut (retired), former Under Secretary of Commerce for Oceans and Atmosphere of the National Oceanic and Atmospheric Administration (NOAA), and an inductee in the Astronaut Hall of Fame. This essay is adapted and excerpted from her book, Handprints on Hubble: An Astronaut's Story of Invention, which is published on November 19, 2019, by MIT Press.