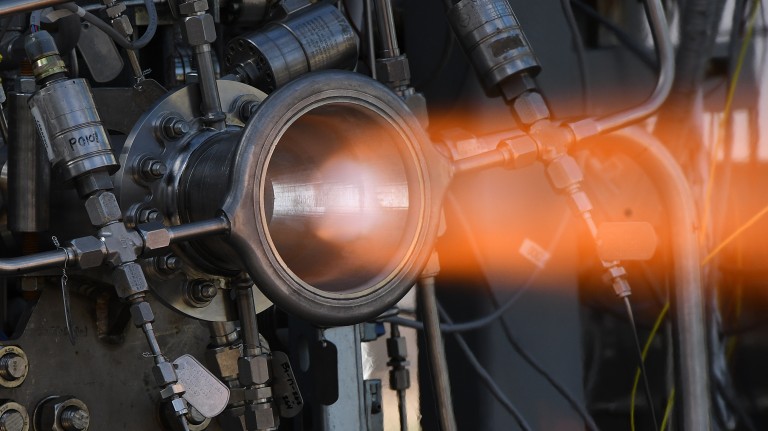

The space agency can finally ensure that additive manufacturing produces parts that withstand the incredible heat experienced by rocket engines.

The news: A newly patented method is called laser wire direct closeout (LWDC). Differing substantially from typical methods of 3-D printing with metal (see “10 Breakthrough Technologies of 2018: 3-D Metal Printing”), it uses a laser and metal wire to create strong metal bonds and precise structures.

The upshot: This process can cut the manufacturing time of rocket nozzles from months to weeks. “Our motivation behind this technology was to develop a robust process that eliminates several steps in the traditional manufacturing process,” says Paul Gradl, a senior propulsion engineer at NASA’s Marshall Space Flight Center. Taking out these steps allows for faster manufacturing.

Next up: The team is looking for additional ways to apply the technology across the industry.

This story first appeared in our future-of-work newsletter, Clocking In. Sign up here!