Intelligent Machines

The Drone Ranger

Grad student Tony Tao makes drones that go faster, fly longer, and save money.

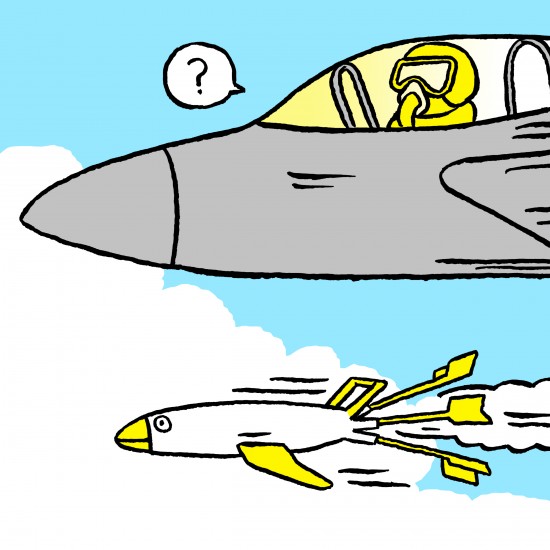

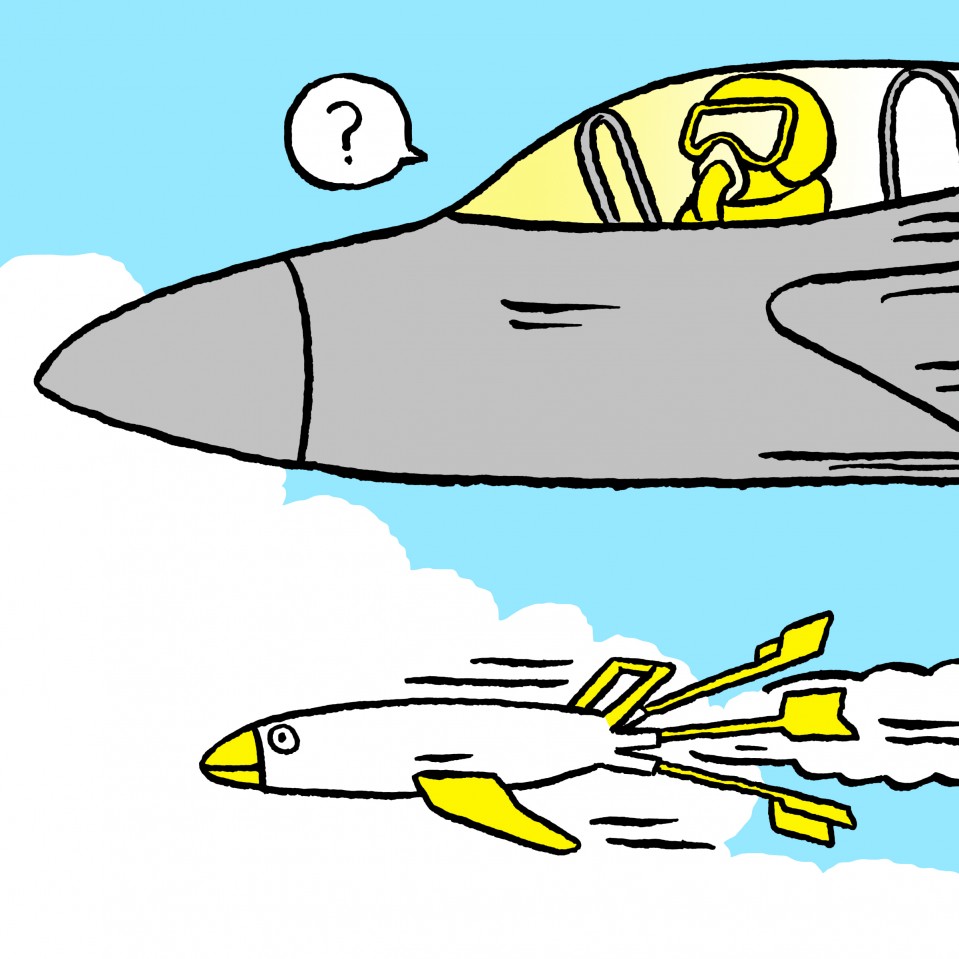

While NASA engineers build bigger, faster-burning rocket engines, Tony Tao, SM ’12, aims for smaller, slower-burning ones. An aero-astro PhD student, Tao is one of three people working on Firefly, a drone propelled by a tiny rocket instead of an electric motor. While even the fastest racing drones cruise at just over 100 miles per hour, Firefly whizzes around at up to 550 miles per hour, thanks to its slow-burning, scaled-down engine. The drone, which weighs two to three pounds, depending on its payload, is designed to deploy from a speeding aircraft, unfold its wings while free-falling, and then zoom around collecting data or posing as a decoy to nearby enemy planes before being discarded.

“We use this burn-rate suppressant, which—via chemical decomposition—cools the flame and changes the flame structure so that it actually burns slower,” Tao says. While a typical model rocket of that size burns for one to three seconds, Firefly’s slow burn allows the drone to fly at rocket-propelled speeds for up to three minutes. “You don’t usually want to put a fire extinguisher inside of your fire, but that’s exactly what we’re doing,” he says.

Firefly, a joint project between MIT’s Lincoln Laboratory and the U.S. Air Force, is the culmination of roughly three years of work. In April, Tao won a $15,000 “Drive It!” Lemelson-MIT Student Prize, in part for his PhD research and for developing Firefly’s predecessor—a tiny electric drone called Locust that can fly at about 70 miles per hour after deploying from an aircraft. Tao says that both Locust and his thesis build on students’ work in 16.82, a capstone class in flight vehicle engineering for which he serves as a teaching assistant.

For his PhD, Tao is spearheading development of adaptable aircraft manufacturing (AAM), a method of producing airplane parts on demand.

Using GPkit, open-source optimization software developed by Warren Hoburg, an assistant professor in aero-astro, the system lets designers plug in variables, such as ideal carrying capacity or flight distance, for hundreds of planes and receive specs on the most efficient way to design each part. Designers can then determine whether they can save money by using parts manufactured for one plane in another, or whether a specialized part can improve efficiency enough to justify producing custom molds.

Tao has used the technique to produce three small planes ranging from five to 25 pounds. The approach reduced both build time and the material used to make molds by more than 50 percent, but it also increased the weight of each aircraft by about 8 percent and decreased efficiency 17 percent. Exact trade-offs will vary by plane, Tao says.

Tao is also helping Lincoln Lab and the Air Force develop Jungle Hawk Owl, a 150-pound drone that will fly for five days straight. Designed to carry communications payloads during natural disasters, the drone could act as a local satellite, allowing high-speed data transmission until area infrastructure gets repaired.

After completing his PhD work this fall, Tao plans to take a job with Lincoln Lab and dive into his next project. “We’re here to explore ideas,” he says.