Computing

Growing Nanotube Forests

Carefully grown carbon-nanotube arrays could be the basis of new energy-storage devices and chip-cooling systems.

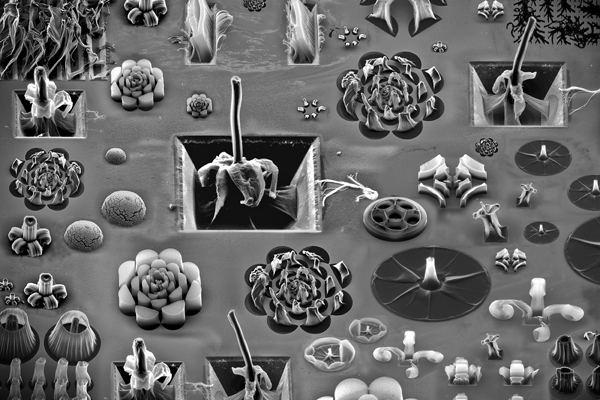

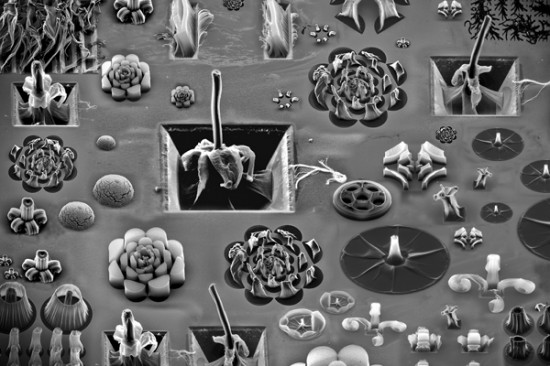

Carbon nanotube arrays could be the basis of high-density energy storage devices and efficient chip cooling systems. The performance of such devices, however, depends on the quality of the nanotubes and the precise structure of the array. So researchers including Anastasios John Hart, assistant professor of mechanical engineering at the University of Michigan, are honing techniques for growing carefully structured forests of high-quality carbon nanotubes. Hart made these images with a scanning electron microscope; all show vertically grown nanotubes.

This is a composite of many images of carbon nanotubes grown on silicon wafers or in cavities etched in the wafers. Each stalklike structure is made up of thousands of nanotubes or more. The catalyst that starts off the nanotubes’ growth is visible under some of them as a dark, shadowlike spot. Structures that appear withered were dipped in liquid after they grew; as the liquid evaporated, the nanotubes shriveled.

This is a composite of many images of carbon nanotubes grown on silicon wafers or in cavities etched in the wafers. Each stalklike structure is made up of thousands of nanotubes or more. The catalyst that starts off the nanotubes’ growth is visible under some of them as a dark, shadowlike spot. Structures that appear withered were dipped in liquid after they grew; as the liquid evaporated, the nanotubes shriveled.