Intelligent Machines

A Shape-Shifting Smartphone Touch Screen

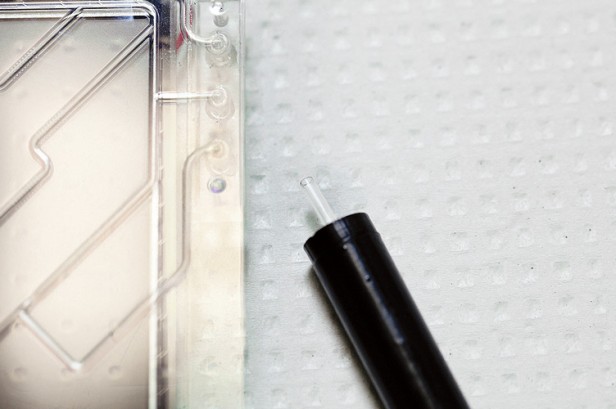

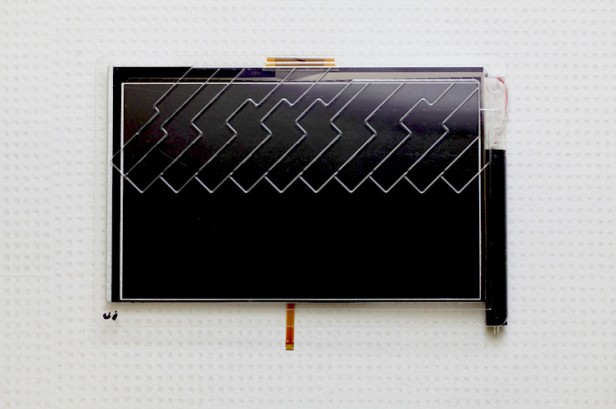

A microfluidic panel lets users push buttons on a flat interface.

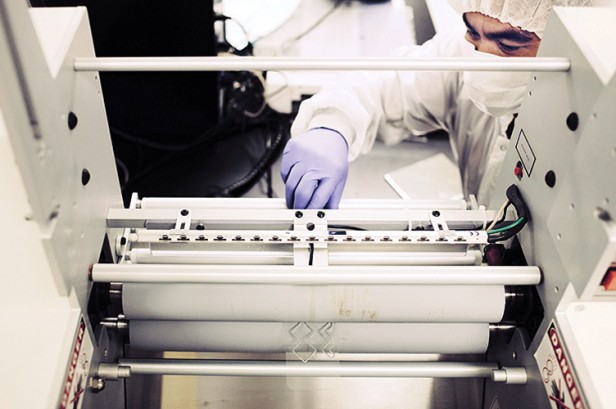

Tactus Technology, a startup in Fremont, California, is prototyping touch-screen hardware with buttons that emerge when you need the feel of a physical keyboard and disappear when you don’t. The approach, in which a fluid-filled plastic panel and cylindrical fluid reservoir replace the usual top layer of glass, is among a crop of emerging technologies aimed at adding tactile feedback to make screens feel like old-fashioned keyboards.

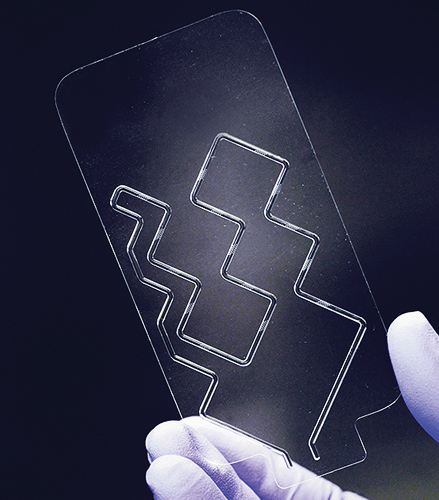

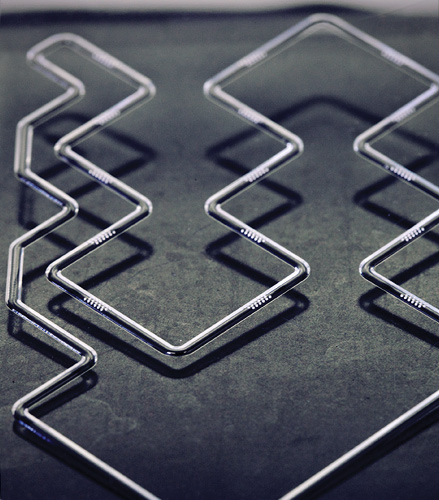

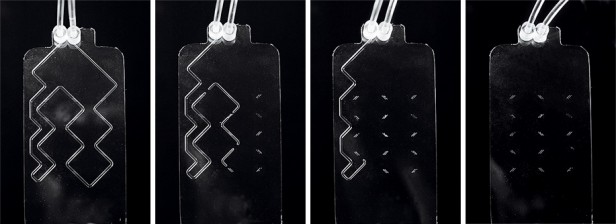

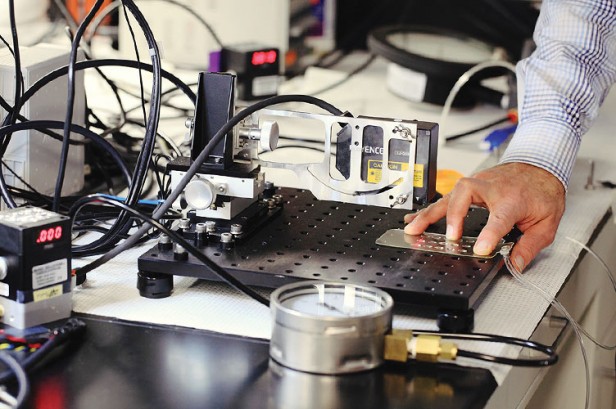

Touch screens are ubiquitous: in 2012, 1.2 billion were made for smartphones and 130 million for tablets, and they’re showing up in everything from game consoles to car navigation interfaces. But typing on them can be difficult. Tactus is trying to solve that problem. The company’s cofounder and chief technology officer, Micah Yairi, helped create a multi-layered panel that contains microchannels filled with a proprietary oil. When signaled by, say, a person launching a text-messaging app, an actuator pumps additional fluid into the channels, and buttons rise up from an elastomeric cover. The user then depresses the button slightly to trigger the touch screen and enter the letter or number. When typing is done, the panel reverts to a flat screen for finger-swiping within one second.

Tactus isn’t the only company recognizing a need for screens to offer tactile or so-called haptic feedback. Many phones already have rudimentary versions; tapping a certain button makes the whole phone buzz. Emerging designs include piezoelectric actuators that make the vibrations more localized. (Apple recently filed a patent on such technology.) And other companies, including Disney and a startup called Senseg, are using electrodes to issue minuscule shocks to your finger, simulating a rough texture.

Tactus’s approach, however, is the only one that allows users to orient their finger on the screen before actually depressing the key, or to rest their fingers on buttons without triggering them. Tactus is working to improve the panel’s appearance and create custom demonstrations for equipment manufacturers. One partner collaborating on prototypes is Touch Revolution, a division of the Taiwanese company TPK, one of the world’s largest touch-screen manufacturers.

Button geometries can be customized during the manufacturing process. In a tablet or smartphone, software would probably change touch–sensitive areas of the display on the fly so that they’d align precisely with button shapes. This would prevent accidental keystrokes when fingers touch areas between raised buttons.

Tactus CEO and cofounder Craig Ciesla, who raised $6 million last year in venture investments, expects products to reach market in late 2013. “It’s really a design tool to give to manufacturers,” he says.