Sustainable Energy

Fail-Safe Nuclear Power

Cheaper and cleaner nuclear plants could finally become reality—but not in the United States, where the technology was invented more than 50 years ago.

In February I flew through the interior of a machine that could represent the future of nuclear power. I was on a virtual-reality tour at the Shanghai Institute of Applied Physics in China, which plans in the next few years to build an experimental reactor whose design makes a meltdown far less likely. Inside the core—a superhot, intensely radioactive place where no human will ever go—the layers of the power plant peeled back before me: the outer vessel of stainless steel, the inner layer of a high-tech alloy, and finally the nuclear fuel itself, tens of thousands of billiard-ball-size spheres containing particles of radioactive material.

Given unprecedented access to the inner workings of China’s advanced nuclear R&D program, I was witnessing a new nuclear technology being born. Through the virtual reactor snaked an intricate system of pipes carrying the fluid that makes this system special: a molten salt that cools the reactor and carries heat to drive a turbine and make electricity. At least in theory, this type of reactor can’t suffer the kind of catastrophic failure that happened at Chernobyl and Fukushima, making unnecessary the expensive and redundant safety systems that have driven up the cost of conventional reactors. What’s more, the new plants should produce little waste and might even eat up existing nuclear waste. They could run on uranium, which powers 99 percent of the nuclear power plants in the world, or they could eventually run on thorium, which is cleaner and more abundant. The ultimate goal of the Shanghai Institute: to build a molten-salt reactor that could replace the 1970s-era technology in today’s nuclear power plants and help wean China off the coal that fouls the air of Shanghai and Beijing, ushering in an era of cheap, abundant, zero-carbon energy.

Over the next two decades China hopes to build the world’s largest nuclear power industry. Plans include as many as 30 new conventional nuclear plants (in addition to the 34 reactors operating today) as well as a variety of next-generation reactors, including thorium molten-salt reactors, high-temperature gas-cooled reactors (which, like molten-salt reactors, are both highly efficient and inherently safe), and sodium-cooled fast reactors (which can consume spent fuel from conventional reactors to make electricity). Chinese planners want not only to dramatically expand the country’s domestic nuclear capacity but also to become the world’s leading supplier of nuclear reactors and components, a prospect that many Western observers find alarming.

The Shanghai Institute’s effort to develop molten-salt reactors, a technology that has sat all but forgotten in the United States for decades, reflects just how daring China’s nuclear ambitions are. Already, the government has invested some two billion Chinese renminbi ($300 million) over the last five years in molten-salt R&D. Building actual plants will require tens of billions more. As with other innovative nuclear technologies in development around the world, there are few guarantees: though people have run small, experimental molten-salt reactors, no one’s ever actually built one at utility scale and hooked it up to the grid. Yet the Chinese government expects to have a commercial-size plant up and running within 15 years, helping to revive the beleaguered nuclear power industry.

The first experiments with molten-salt reactors were carried out at Oak Ridge National Laboratory, in Tennessee, under its director Alvin Weinberg in the late 1950s. Today’s Chinese program, in fact, is the fruit of a unique and somewhat controversial partnership between Oak Ridge and the Shanghai Institute. The U.S. research program went on for more than a decade but was eventually shut down in favor of the technology used in the vast majority of nuclear power plants today. In retrospect, that decision contributed not only to the demise of a promising nuclear technology but also to the long stagnation of the industry.

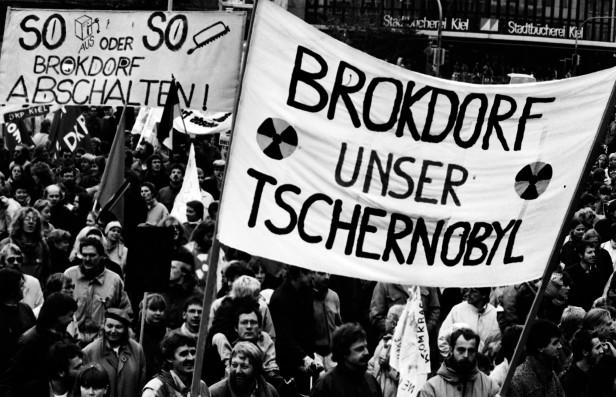

Today, though, the world needs nuclear energy more than ever if we are to limit climate change. According to the International Energy Agency, the world’s nuclear capacity needs to more than double by midcentury if we are to stay within 2 °C of warming. As it stands now, that seems unlikely. Several countries, including China and India, have embarked on massive nuclear power build-outs, but most will entail big, conventional reactors—technology that is too expensive for much of the rest of the world. Even countries, such as Germany, that can afford nuclear power are phasing it out because they fear another disaster. That makes the fail-safe nuclear power plants being developed at the Shanghai Institute of paramount urgency.

After my virtual tour, Kun Chen, one of the molten-salt program’s lead scientists, walked me back to the institute’s main administration building. Snow had fallen overnight, and it was bitterly cold. In the auditorium a small crowd of staffers had gathered for a talk by Xu Hongjie, the director of the molten-salt program. It was the week before the long lunar new year holiday, and the institute’s annual banquet was being held that night. Xu spoke for more than two hours about the history of molten-salt technology and its prospects for the future.

“This has been China’s dream for a half-century,” he said. “Previously, we lacked the necessary knowledge and skills to make it a reality. Now we have the resources and the technology and the expertise. Now we can do it.”

Chain reactions

Alvin Weinberg first came to Oak Ridge in 1945, just after its laboratories had been built in the northern Tennessee hills to make weapons-grade uranium and plutonium. A veteran of the Manhattan Project, Weinberg became director of the rapidly growing national lab in 1955 and held the position until 1973. He was a pioneering nuclear physicist and a philosopher of nuclear power who used the phrase “Faustian bargain” to describe the tension between industrialized society’s thirst for abundant energy and the extreme vigilance needed to keep nuclear power safe. To make this energy source both clean and extremely cheap, he believed, the link between nuclear power and nuclear weapons would have to be severed. And the way to break that link was the thorium molten-salt reactor.

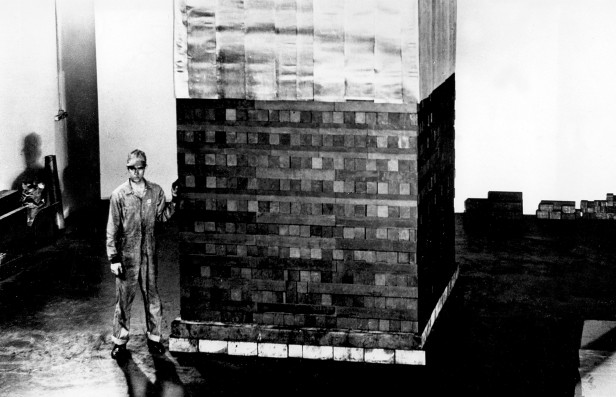

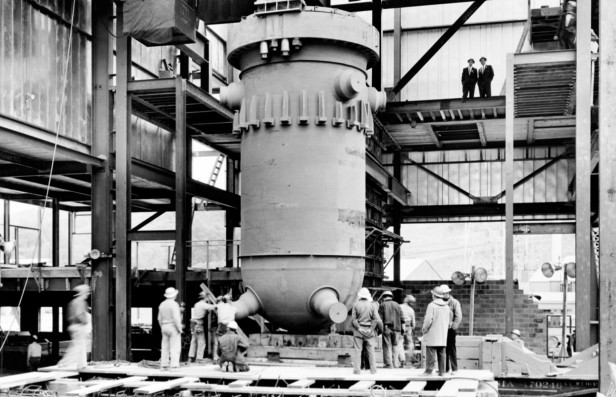

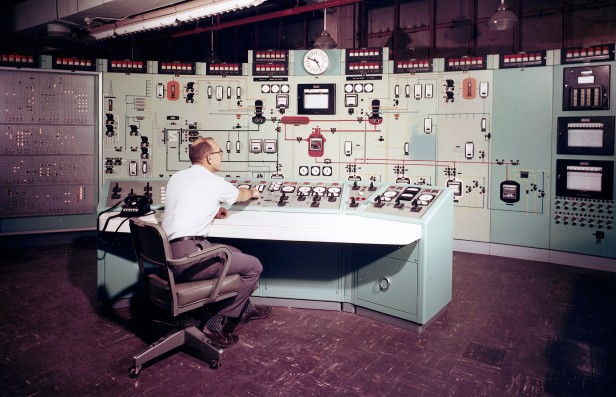

Under Weinberg’s leadership, a team of enthusiastic young chemists, physicists, and engineers operated a small, experimental molten-salt reactor from 1965 to 1969. That reactor at Oak Ridge ran on uranium; Weinberg’s eventual goal was to build one that would run exclusively on thorium, which, unlike uranium, cannot easily be made into a bomb. But the molten-salt experiment was abandoned in the early 1970s. One big reason was that Weinberg managed to alienate his superiors by warning of the dangers of conventional nuclear power at a time when dozens of such reactors were already under construction or in the planning stages.

By the end of the century, the U.S. had built 104 nuclear reactors, but construction of new ones had all but come to a halt, and the technology remained stuck in the 1970s. Because conventional reactors require huge, costly containment vessels that can blow up in extreme conditions, and because they use extensive external cooling systems to make sure the solid-fuel core doesn’t overheat and cause a runaway reaction leading to a meltdown, they are hugely expensive. Two new reactors being built now in Georgia could cost $21 billion, 50 percent over the original estimate of $14 billion. All that for 40-year-old technology.

Today, though, as climate change accelerates and government officials and scientists seek a nuclear technology without the expensive problems that have stalled the conventional version, molten salt is enjoying a renaissance. Companies such as Terrestrial Energy, Transatomic Power, Moltex, and Flibe Energy are vying to develop new molten-salt reactors. Research programs on various forms of the technology are under way at universities and institutes in Japan, France, Russia, and the United States, in addition to the one at the Shanghai Institute. Besides the work going into developing solid-fuel reactors that are cooled by molten salt (like the one I toured virtually in Shanghai), there are even more radical designs that also use radioactive materials dissolved in molten salt as the fuel (as Weinberg’s experiment did).

Like all nuclear plants, molten-salt reactors excite atoms in a radioactive material to create a controlled chain reaction. The reaction unleashes heat that boils water, creating steam that drives a turbine to generate electricity. Solid-fuel reactors cooled with molten salt can run at higher temperatures than conventional reactors, making them more efficient, and they operate at atmospheric pressures—meaning they do not require expensive vessels of the sort that ruptured at Chernobyl. Molten-salt reactors that use liquid fuel have an even more attractive advantage: when the temperature in the core reaches a certain threshold, the liquid expands, which slows the nuclear reactions and lets the core cool. To take advantage of this property, the reactor is built like a bathtub, with a drain plug in the bottom; if the temperature in the core gets too high, the plug melts and the fuel drains into a shielded tank, typically underground, where it is stored safely as it cools. These reactors should be able to tap more of the energy available in radioactive material than conventional ones do. That means they should dramatically reduce the amount of nuclear waste that must be handled and stored.

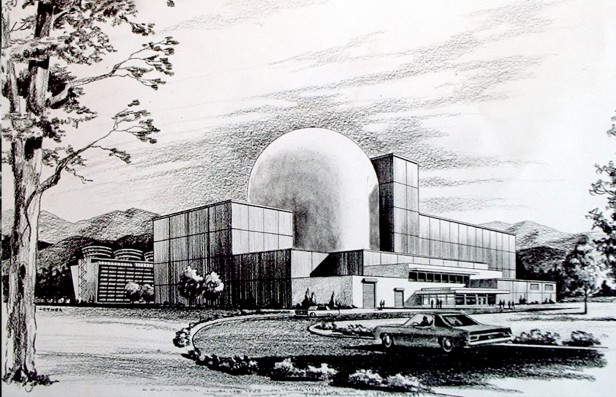

Because they don’t require huge containment structures and need less fuel to produce the same amount of electricity, these reactors are more compact than today’s nuclear plants. They could be mass-produced, in factories, and combined in arrays to form larger power plants.

All of that should make them cheaper to build. Unlike wind and solar, which have gotten far less expensive over time, nuclear plants have become much more so. According to the U.S. Energy Information Administration, the inflation-adjusted cost of building a nuclear plant rose from $1,500 per kilowatt of capacity in the early 1960s to more than $4,000 a kilowatt by the mid-1970s. In its latest calculation, in 2013, the EIA found that the figure had risen to more than $5,500—more expensive than a solar power plant or onshore wind farm, and far more than a natural-gas plant. That up-front cost is amplified by the large size of the reactors; at the average cited by the EIA, a one-gigawatt plant would cost $5.5 billion, a risky investment for any company.

Those up-front costs are balanced by the fact that nuclear plants are relatively cheap to operate: at new plants the levelized cost of electricity, which measures the cost of power generated over the lifetime of the plant, is $95 per megawatt-hour, according to the EIA—comparable to the cost of electricity from coal-fired plants, and less than solar power ($125 a megawatt-hour). Still, natural-gas plants are far cheaper to build, and the cost of the electricity they produce ($75 a megawatt-hour, according to the EIA) is also lower. Tightening regulations on carbon emissions makes nuclear more attractive, but lowering the cost of construction is critical to the future of zero-carbon nuclear power.

That is the pitch being made by a new crop of startups working on advanced nuclear reactors, several of them funded by Silicon Valley investors. Transatomic Power, for instance, was founded by a pair of MIT PhDs, Leslie Dewan and Mark Massie, who have designed a 520-megawatt plant (about the size of an average coal plant today) that they think can be built for $2 billion, or $3,846 per kilowatt of capacity. That is in line with the cost of building a solar power plant—but would have the huge advantage of being able to produce power continuously, not just when the sun shines. Terrestrial Energy, which recently won a research grant from the Canadian government to build a prototype reactor, says that its molten-salt reactor could eventually be built for as little as $2,000 a kilowatt.

But even though molten-salt designs have energized inventive young technologists, getting a novel nuclear power technology licensed and built in the U.S. remains a daunting prospect. Simply applying for a license from the Nuclear Regulatory Commission can take years and cost hundreds of millions of dollars, which is why some of these startups may never get off the ground. What’s more, even $2 billion would be a lot of money for investors and utilities to spend on an unproven technology with questionable financial advantages. Which is why the program closest to producing a working reactor is in the People’s Republic of China.

Think big

Even as the original experiment with molten-salt technology was winding down in the U.S. in the 1970s, a small group of researchers at the Shanghai Institute of Applied Physics, part of the Chinese Academy of Sciences, was launching its own investigation into thorium-fueled molten-salt reactors. But China, which would not start up its first nuclear power plant until 1991, lacked the expertise and the money to develop the sophisticated machinery and expensive materials in advanced reactors. By the 21st century, like all other countries with nuclear power, China relied on conventional reactors. But the embers of the concept still glowed in the minds of Chinese nuclear scientists.

From the Chinese point of view, thorium has a particular advantage: while mainland China has a small percentage of the world’s uranium, it has plenty of thorium. Having an abundant source of carbon-free energy would solve several of China’s energy dilemmas at one go. “In the eyes of the central government, we are not here to do mature technologies—we have to create something new, something strategic,” says Kun Chen, the molten-salt scientist who led my virtual tour in Shanghai. “You have to think big.”

Educated at the prestigious University of Science and Technology of China, in Hefei, Chen earned a PhD from Indiana University and worked for several years at Argonne National Laboratory (which, like Oak Ridge, is part of the U.S. Department of Energy). But he came back to China to build a world-changing reactor.

He heard about it in 2009, when he visited Shanghai to present a seminar at the Institute of Applied Physics. A scientist there told him about the thorium molten-salt reactor—a project not yet funded or announced. “Our team got most of the technical documents from the Web—they were posted by the Oak Ridge team,” recalls Xu Hongjie, the director of the molten-salt program, shaking his head in either admiration or amazement at the openness of the Americans. “They posted everything there for free.”

At Xu’s urging, Chen joined the Shanghai Institute in 2010, and today he is in charge of collaborating with Oak Ridge. The U.S. lab is contributing research on materials, control systems, and computer simulations to the project and has built a large molten-salt testing facility that was funded by the Chinese Academy of Sciences. While some scientists and nuclear-power advocates vehemently oppose the idea of helping China build a world--leading nuclear industry, many Oak Ridge engineers are just eager to see molten-salt reactors built somewhere. “One of the important things to realize is that a number of key people in molten-salt reactors are retiring very fast or passing away,” says David Holcombe, who heads Oak Ridge’s collaboration with the Shanghai Institute. “You can’t just import a new set of staff if we’re going to maintain this capability. China is providing the funding that allows us to transfer that knowledge, to gain practical experience at building and operating these reactors.”

To start, the Shanghai Institute plans to take a hybrid approach, using molten salt to cool a solid-fuel core similar to the ones in conventional nuclear plants. Then, Chen says, the team will progress to liquid fuels to fully realize the technology’s potential for safety and efficiency. At first the fuel will be uranium, but the Chinese engineers plan to shift later to thorium.

The time lines are aggressive, at least by the standards of the nuclear industry. The Shanghai Institute aims to start up a commercial-scale solid-fuel plant by 2030 and a 100-megawatt demonstration liquid-fuel reactor by 2035. Much of the current work, Chen told me, focuses on solving the complex plumbing challenges associated with the highly corrosive molten salt. I was struck by the confidence and idealism of the young scientists working at the institute—an optimism not seen in U.S. nuclear circles since Weinberg’s day.

On my last day in Shanghai, Kun Chen and I strolled around the institute’s grounds. The snow was mostly gone, but the icy wind was still sharp. He showed me the campus’s latest construction project: a three-story-high, warehouse-size building to house the thorium molten-salt program. All the chemistry labs, all the machine shops, all the computers, all the offices and the test loops and pumps and prototypes, will be housed here when the building opens later this year. It was just a shell at the time, but it was a symbol of China’s commitment to the next nuclear era. The dream of American scientists at Oak Ridge, a half-century ago, is taking shape here, thousands of miles away.

Advertisement